The oil, gas, and energy industries are inherently high-risk sectors due to the presence of highly flammable and explosive substances, including crude oil, natural gas, and volatile chemicals. Fires or explosions in these environments can have devastating consequences, resulting in significant financial losses, environmental damage, and loss of life. As such, fire safety in oil, gas, and energy facilities is paramount, requiring specialized fire safety systems and strict adherence to safety protocols to prevent large-scale disasters.

Fire Hazards in the Oil, Gas, and Energy Sectors

Fire hazards in these industries stem from the materials being handled, as well as the processes involved in extracting, refining, and transporting fuel. Key fire risks include:

- Flammable Liquids and Gases: The storage, transportation, and processing of hydrocarbons—whether in liquid (crude oil, gasoline) or gas (natural gas, propane) form—pose significant fire risks. These substances can ignite if exposed to heat, sparks, or open flames.

- Chemical Reactions: Refineries and energy plants often involve chemical processes that generate heat, pressure, and flammable byproducts. A failure in equipment or containment systems can lead to uncontrolled reactions, resulting in fires or explosions.

- Electrical Equipment: Large-scale energy facilities require extensive electrical infrastructure to power operations. Faulty wiring, overloaded circuits, or equipment failures can lead to electrical fires, which may escalate quickly in environments containing flammable materials.

- High-Pressure Systems: In oil and gas extraction and transportation, high-pressure pipelines and vessels are common. A rupture or failure in these systems can release flammable liquids or gases into the air, increasing the likelihood of fires.

Specialized Fire Safety Systems

Due to the unique hazards in the oil, gas, and energy industries, standard fire protection measures are often insufficient. These environments require specialized fire safety systems designed to suppress fires involving flammable and explosive substances quickly and effectively.

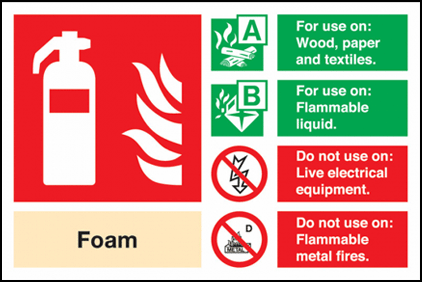

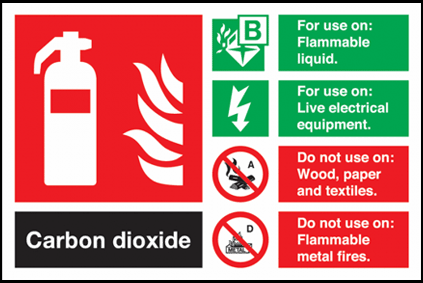

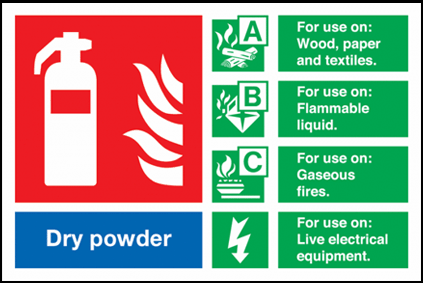

- Specialized Fire Extinguishers: Fire extinguishers used in oil and gas facilities must be capable of handling flammable liquid and gas fires. Foam and dry chemical extinguishers are commonly used, as they are effective at smothering fires fueled by oil, gas, and chemicals. Water-based extinguishers are generally unsuitable due to the risk of spreading flammable liquids or causing explosive reactions.

- Foam Suppression Systems: Foam fire suppression systems are highly effective in controlling fires involving oil and gas. These systems create a blanket of foam that suffocates the fire, preventing oxygen from reaching the fuel source. Foam suppression is widely used in storage tanks, refineries, and offshore platforms.

- Inert Gas Systems: In confined spaces like control rooms or enclosed equipment areas, inert gas suppression systems are used. These systems release gases such as nitrogen or carbon dioxide to displace oxygen, effectively extinguishing fires without causing damage to sensitive equipment or creating a toxic environment.

- Deluge Systems: Deluge systems are a type of sprinkler system designed for high-hazard environments. In the event of a fire, these systems release large volumes of water or foam simultaneously to flood the affected area, cooling it down and controlling the fire. Deluge systems are common in processing plants, fuel storage areas, and offshore platforms.

- Explosion Suppression Systems: Certain facilities, such as natural gas plants, are prone to explosions due to the buildup of combustible gases. Explosion suppression systems detect the initial stages of an explosion and release a suppressant to quench the fireball before it escalates into a full-scale explosion.

Fire Safety in Oil Refineries

Oil refineries process large quantities of crude oil into usable products like gasoline, diesel, and other petrochemicals. These facilities are particularly vulnerable to fires due to the complex chemical reactions involved and the storage of large volumes of flammable liquids. Key fire safety measures include:

- Tank Fire Protection: Storage tanks in refineries hold vast amounts of oil, which can ignite if exposed to heat or sparks. Tank fire protection systems, such as foam pourers and water cooling systems, are essential to prevent fires from spreading to adjacent tanks or areas.

- Process Unit Safety: Refineries contain multiple process units where crude oil is heated, separated, and chemically treated. These units are equipped with fire detection systems, explosion suppression systems, and emergency shutdown mechanisms to minimize the risk of fires.

- Emergency Shutdown Systems: In the event of a fire, refineries have emergency shutdown systems that halt the flow of fuel and isolate areas affected by the fire. This limits the potential for escalation and gives fire response teams a better chance of controlling the situation.

Fire Safety on Offshore Platforms

Offshore oil and gas platforms present unique challenges in fire safety due to their isolated locations and the need to manage large quantities of flammable materials in a confined space. Fire safety measures on these platforms include:

- Water Deluge Systems: Offshore platforms are equipped with water deluge systems that can rapidly cool equipment and suppress fires. These systems are vital for protecting critical areas like drilling rigs, production modules, and fuel storage tanks.

- Helideck Fire Safety: Helicopters are often used to transport workers to and from offshore platforms, and the helideck presents a potential fire hazard during landings and take-offs. Specialized foam suppression systems are installed to deal with fires caused by helicopter fuel spills.

- Blowout Preventers (BOPs): Blowouts, where uncontrolled oil or gas escapes from a well, can lead to catastrophic fires. Blowout preventers are mechanical devices installed at the wellhead to seal the well in the event of a blowout, reducing the risk of fire.

Fire Safety in Power Plants and Energy Facilities

Power generation facilities, whether they are coal, natural gas, or nuclear, also face significant fire risks. Protecting these plants from fire is critical to ensure the continuity of energy supply and prevent hazardous incidents.

- Turbine Protection: In power plants, turbines generate electricity by converting energy from fuel combustion or steam. These turbines can overheat, creating a fire hazard. Fire detection and suppression systems, including gas-based or water mist systems, are essential to protect turbines from fire damage.

- Transformer Protection: Electrical transformers, which step up or step down voltage levels, can overheat or suffer faults that cause fires. Oil-filled transformers are particularly prone to fire, so foam or water-based suppression systems are installed to manage these risks.

- Control Room Safety: Control rooms house sensitive electrical and electronic equipment used to manage plant operations. These rooms are often equipped with inert gas suppression systems that can quickly extinguish fires without damaging the equipment or endangering personnel.

Emergency Response and Evacuation Plans

In high-risk environments like oil refineries, gas processing plants, and offshore platforms, having a well-defined emergency response plan is crucial. This includes:

- Evacuation Procedures: Facilities must have clear evacuation routes and muster points, with regular drills conducted to ensure that all personnel know how to evacuate safely in the event of a fire. Offshore platforms, in particular, need evacuation systems such as lifeboats or helicopters.

- Firefighting Teams: Many oil, gas, and energy facilities have their own onsite firefighting teams who are trained to respond to fires quickly. These teams must be equipped with the appropriate protective gear and fire suppression tools to manage fires involving hazardous materials.

- Emergency Shutdown Procedures: In the event of a fire, emergency shutdown systems automatically halt operations, isolate fuel sources, and reduce pressure in pipelines and vessels to prevent further escalation.

Compliance with Fire Safety Regulations

The oil, gas, and energy industries are heavily regulated to ensure fire safety. These facilities must comply with national and international fire safety standards, including:

- NFPA (National Fire Protection Association) Standards: The NFPA provides fire safety codes and standards specifically designed for the oil, gas, and energy sectors. Compliance with these standards ensures that facilities implement best practices for fire protection.

- API (American Petroleum Institute) Guidelines: The API publishes guidelines for fire safety in petroleum and natural gas facilities, covering everything from fire extinguisher placement to the design of fire suppression systems.

- Regular Inspections and Audits: Facilities must undergo regular fire safety inspections and audits to ensure that all systems are functioning correctly and that the facility remains compliant with fire safety regulations.

Conclusion

In the oil, gas, and energy sectors, where the risks of fire are ever-present, robust fire safety systems are essential to protect personnel, infrastructure, and the environment from large-scale disasters. Specialized fire extinguishers, foam suppression systems, and emergency response plans form the backbone of fire protection in these high-risk industries. By adhering to stringent safety regulations, conducting regular maintenance, and training staff in emergency procedures, these industries can mitigate the risks of fire and ensure the continued safe operation of critical infrastructure.